Warehouse Management System (WMS)

Transform your warehouse into a precision execution engine, powered by SCOTI™, the intelligent supply chain orchestration platform. Our WMS unifies inbound logistics, inventory management, fulfillment, and automation into a single real-time control layer. Purpose-built for enterprise scale, it delivers measurable ROI through intelligent automation, seamless integration, and operational excellence across every function of your distribution center.

Why Warehouse Operations Struggle

Enterprise warehouses face mounting pressure to deliver faster and more accurately, yet most operations are held back by systemic inefficiencies.

Fragmented Execution Flows

Disconnected systems create delays, duplicate work, and fragmented warehouse operations, limiting end-to-end visibility.

Slow Time to Value from Legacy Systems

Traditional WMS deployments are slow and rigid, making adaptation to changing business needs costly and time-consuming.

Manual, Labor-Heavy Processes

Manual, paper-based processes slow operations and increase errors, pulling teams away from higher-value work.

Limited Real-Time Visibility

Delayed reporting prevents real-time visibility, forcing managers to react instead of optimize proactively.

Integration Gaps Across Systems

Disconnected ERP and yard systems create data conflicts that drive inventory imbalance and fulfillment delays.

Inflexible Scalability

Rigid architectures fail to scale during seasonal peaks, leading to bottlenecks and operational downtime.

A Smarter Way to Run the Warehouse

Our WMS replaces complexity with clarity, manual processes with intelligent automation, and reactive firefighting with proactive orchestration. Built for the demands of modern distribution, it delivers the control, speed, and intelligence enterprises need to compete.

End-to-End Execution Control

A single platform that controls warehouse execution end to end, delivering real-time visibility from dock to door.

ROI-Driven Automation

Intelligent task orchestration and automation that reduces errors, increases throughput, and delivers ROI in under 12 months.

Enterprise-Ready, Cloud-Native Platform

A scalable microservices architecture built for high-volume, multi-site warehouse operations.

The Four Execution Pillars of SCOTI™ WMS

Comprehensive capabilities organized around the essential functions of warehouse excellence. Each pillar delivers standalone value while integrating seamlessly to create a unified execution platform.

Inbound Logistics & Inventory Integrity

Precise, compliant receiving that ensures inventory accuracy from the moment goods arrive.

Fulfillment Orchestration

Intelligent coordination of orders, labor, and execution to maximize throughput and service performance.

Extended Enterprise Integration

A unified WMS execution hub that seamlessly connects ERP, TMS, YMS, and analytics systems.

Advanced Automation & AI

Autonomous warehouse orchestration powered by robotics, IoT, and agentic AI.

Inbound Logistics & Inventory Integrity

Establish the foundation for operational excellence with comprehensive inbound control and inventory accuracy. From advance shipment notification through putaway and cycle counting, ensure every item is received correctly, stored intelligently, and tracked with precision.

Validate inbound arrivals, pre-allocate dock doors, and prepare resources to accelerate receiving throughput.

Coordinate carrier appointments and dock capacity while capturing accurate receiving details.

Enforce receiving standards, flag discrepancies, and track supplier compliance.

Intelligently slot inventory based on demand and continuously rebalance locations as patterns change.

Maintain perpetual inventory accuracy through continuous, exception-based counting.

Intelligently process returns and route inventory to resale, repair, or disposal based on business rules.

Fulfillment Orchestration

Transform order fulfillment from a labor-intensive bottleneck into a competitive advantage. Intelligently sequence work, optimize labor deployment, and orchestrate picking, packing, and shipping with the precision and speed that today's customers demand.

Order Allocation and Prioritization

Apply intelligent rules to route orders, balance workloads, and meet service commitments at scale. This foundational layer ensures that the right work is started at the right time.

Labor and Task Orchestration

Dynamically assign and rebalance work based on skill, location, and real-time demand.

Advanced Picking Methods

Support multiple picking strategies and dynamically select the optimal method for each order.

Cartonization and Packing Optimization

Automatically optimize carton selection and packing to reduce material use and dimensional weight costs.

Shipment Planning and Consolidation

Consolidate shipments and optimize pallet builds to maximize carrier utilization and reduce freight costs.

Value-Added Services

Execute value-added services with guided workflows and quality controls to ensure accuracy and brand consistency throughout the final stage of fulfillment.

Enterprise Scale Performance

Proven capacity to orchestrate over 500,000 order lines daily with throughput exceeding 50,000 units per hour during peak periods. Support multi-site networks with unified visibility and control across distribution centers, ensuring consistent execution and service levels enterprise-wide.

Extended Enterprise Integration

Your WMS should not operate in isolation. Position it as the execution hub that connects upstream planning systems with downstream transportation and customer systems.

Seamless Connectivity Across the Stack

ERP Integration

Native ERP connectivity with bi-directional synchronization.

TMS and YMS Integration

Seamlessly exchange shipment data and coordinate docks and yards.

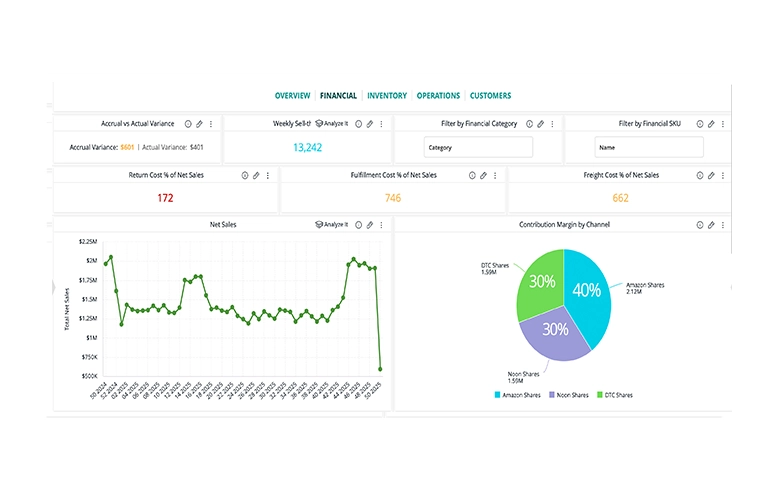

Business Intelligence

Stream operational data to analytics platforms for real-time dashboards.

Demand Planning Integration

Share execution data to improve forecast accuracy and replenishment.

EDI, APIs, and Connectivity

Support industry-standard protocols with flexible middleware.

Eliminate data silos and manual handoffs. Real-time synchronization ensures every system has accurate information across your supply chain.

Advanced Automation & Artificial Intelligence

Evolve from manual execution to autonomous warehouse orchestration. Integrate material handling automation, harness IoT sensor data, and deploy AI agents that predict problems before they occur—transforming your WMS from a transactional system into an intelligent control platform.

WCS and Robotics Integration

Seamlessly orchestrate automated and manual workflows through direct connectivity with warehouse automation systems.

IoT and Sensor Data Ingestion

Capture real-time IoT telemetry to validate processes, trigger alerts, and optimize resources dynamically.

Computer Vision for Inspection

Use machine vision to automate quality checks and verify accuracy across packing and handling.

Agentic AI for Proactive Prevention

AI agents proactively detect risks and recommend actions before disruptions impact operations.

Control-Tower Dashboards

A unified command center delivering real-time visibility, predictive insight, and proactive control.

Real Results. Fast ROI.

Leading e-commerce enterprises leverage CSCS to eliminate operational blind spots and unlock significant improvements across cost, risk, and customer experience. Our clients consistently achieve measurable results within the first 90 days.

<1

Year to ROI

Accelerated implementation that delivers immediate productivity and rapid time to-value.

30%

Labor Cost Reduction

Intelligent task assignment and work balancing that eliminate wasted motion and boost workforce productivity.

99.8%

Inventory Accuracy

Real-time tracking and exception-based controls maintain perpetual inventory accuracy.

Sustainable Competitive Advantage

These are not one-time gains. Our WMS creates a platform for continuous improvement, with performance that improves as the system learns from your operations and as you progressively adopt advanced capabilities. Customers report sustained productivity improvements year-over-year as they optimize slotting, refine wave strategies, and expand automation. The platform scales seamlessly as volumes grow, ensuring performance remains consistent during peak seasons and business expansion.

Built on a Cloud-Native Foundation

Modern warehouse operations demand modern architecture. Our cloud-native WMS delivers the agility, scalability, and resilience legacy systems cannot match with the security and reliability required by global enterprises. Built for mission-critical environments, the platform provides advanced governance, monitoring, and compliance controls that give IT full oversight, while operations teams benefit from rapid deployment, seamless upgrades, and zero infrastructure burden.

Ready to Get Started?

See how SCOTI™ delivers real-time control, intelligent automation, and measurable ROI. Schedule a personalized demo to experience the platform in action.

Intelligent Supply Chain Starts Here

Make Your Supply Chain Smarter and Faster with AI

Our Technology and Strategic Partners